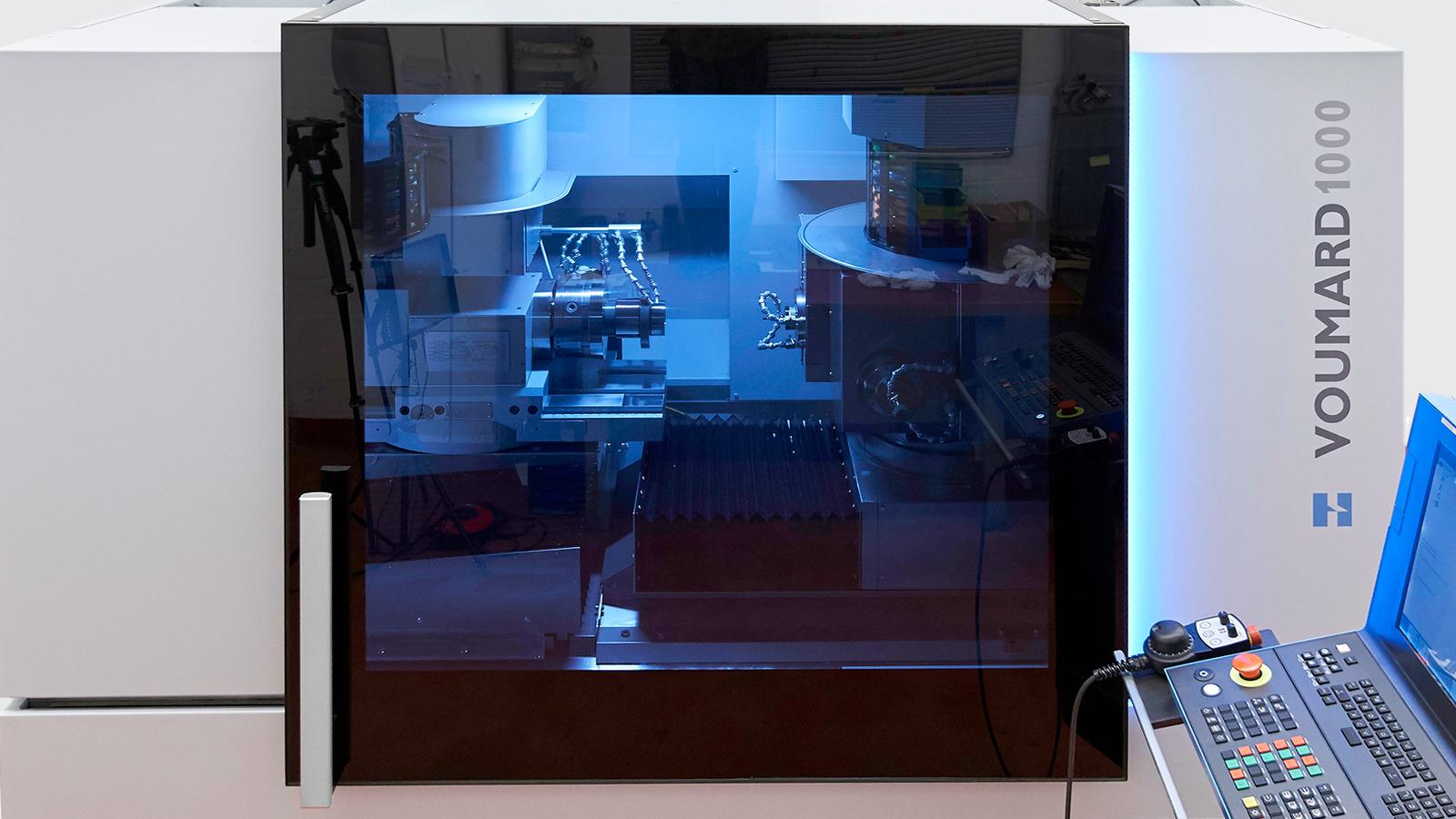

Polycarbonate and silicate glass, fully laminated. It couldn't be better!

SICURTEC_GUARD is currently the absolute high-end solution among machine safety windows on the market.

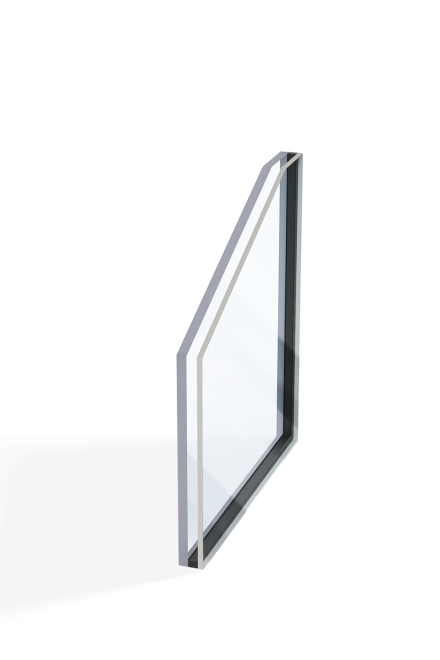

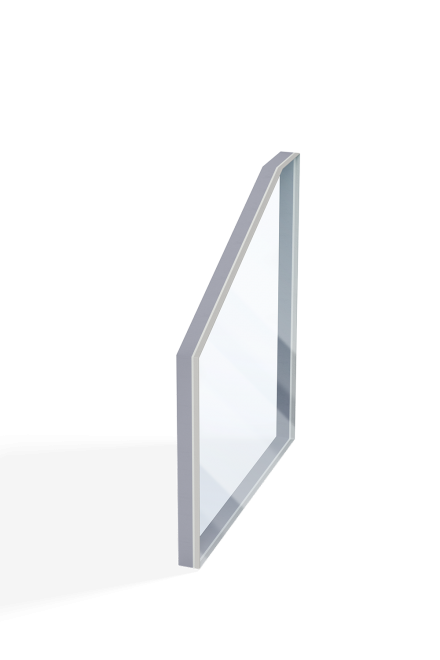

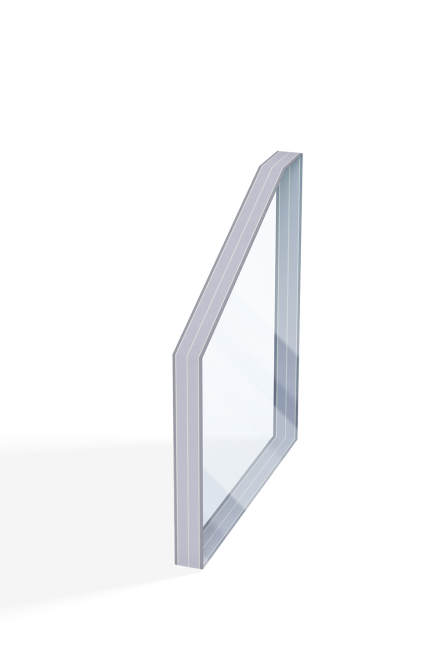

It consists of highly resistant and highly elastic polycarbonate, which is connected over the entire surface with extremely hard silicate glass by using a special adhesive. Thanks to this special adhesive, polycarbonate and silicate glass form an unbeatable unit. The polycarbonate ensures enormous retention, the silicate glass guarantees perfect protection against chemical influences and the adhesive connection ensures protection against machine failures, since no glass fragments get into the work area in the event of a potential impact. In addition, the special adhesive significantly increases the retention capacity. With SICURTEC_GUARD, nothing is left to chance in the production process and you get a product for maximum safety.

Our product is tested, certified and has a lot more advantages to offer

- Ideal for all high-speed machine tools

- Tested and certified according to all relevant standards

- Protects employees from serious injuries

- Protects the inventory from costly damage

- Perfect view of all manufacturing processes

- Available in various sizes

- Special solutions possible

- Perfect protection against chemical influences

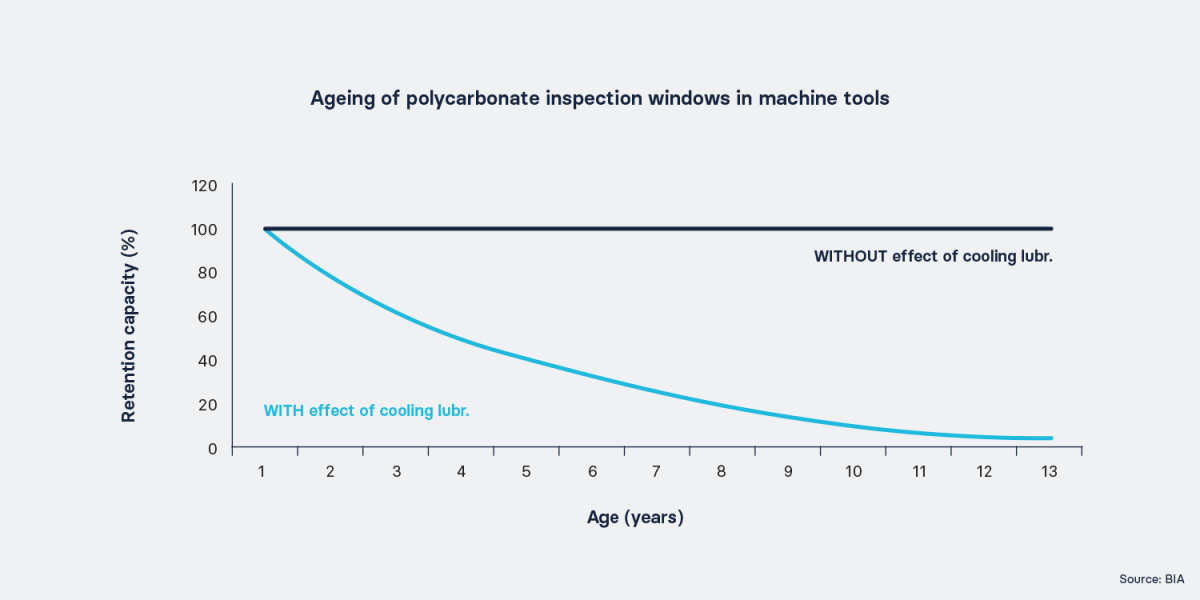

- Particularly durable compared to pure polycarbonate

- Even fewer mirror effects

- Window replacement every 5 years instead of every 2 years

- Even more restraint

- No glass fragments in the machine room in the event of a potential impact

- No machine failures in the event of a potential impact

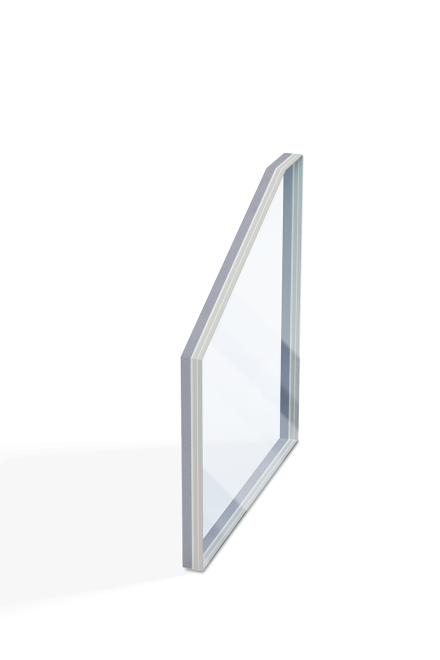

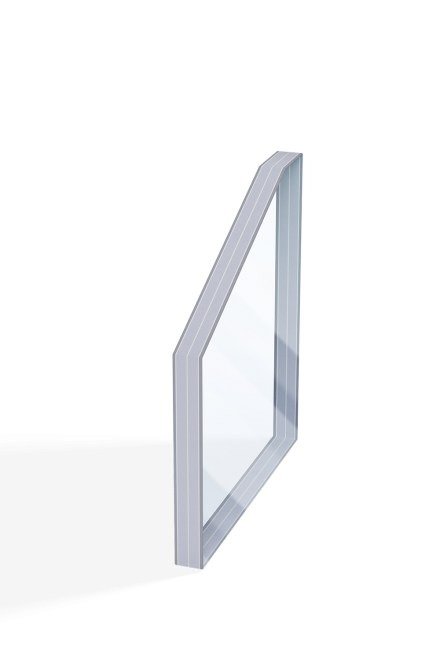

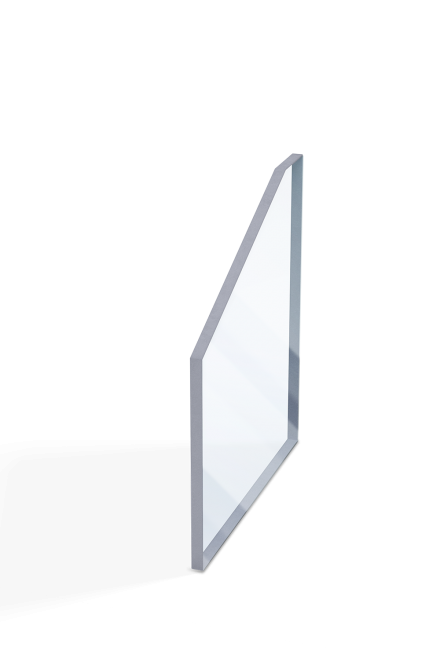

Frame systems for perfect sealing of the machine safety window

Chemical influences, such as contact with cooling lubricants, can cause considerable damage to machine safety windows. Unless, for example, the window with glass is glued into a stainless steel frame. As a all-round provider, we provide you with three standard frame profiles with L, Z and S profiles. Due to the product flexibility, all three profile types can be adapted to any pane thickness according to the desired retention effect. Same applies to frames, which are developed by us especially to customer requirements and which are produced as already glued and finished elements.

Further edge protection

Are you using an existing frame profile? No problem. The options NBR and ALU are compatible with every frame profile.