Multi-layer polycarbonate-acrylic-glass composite for special applications

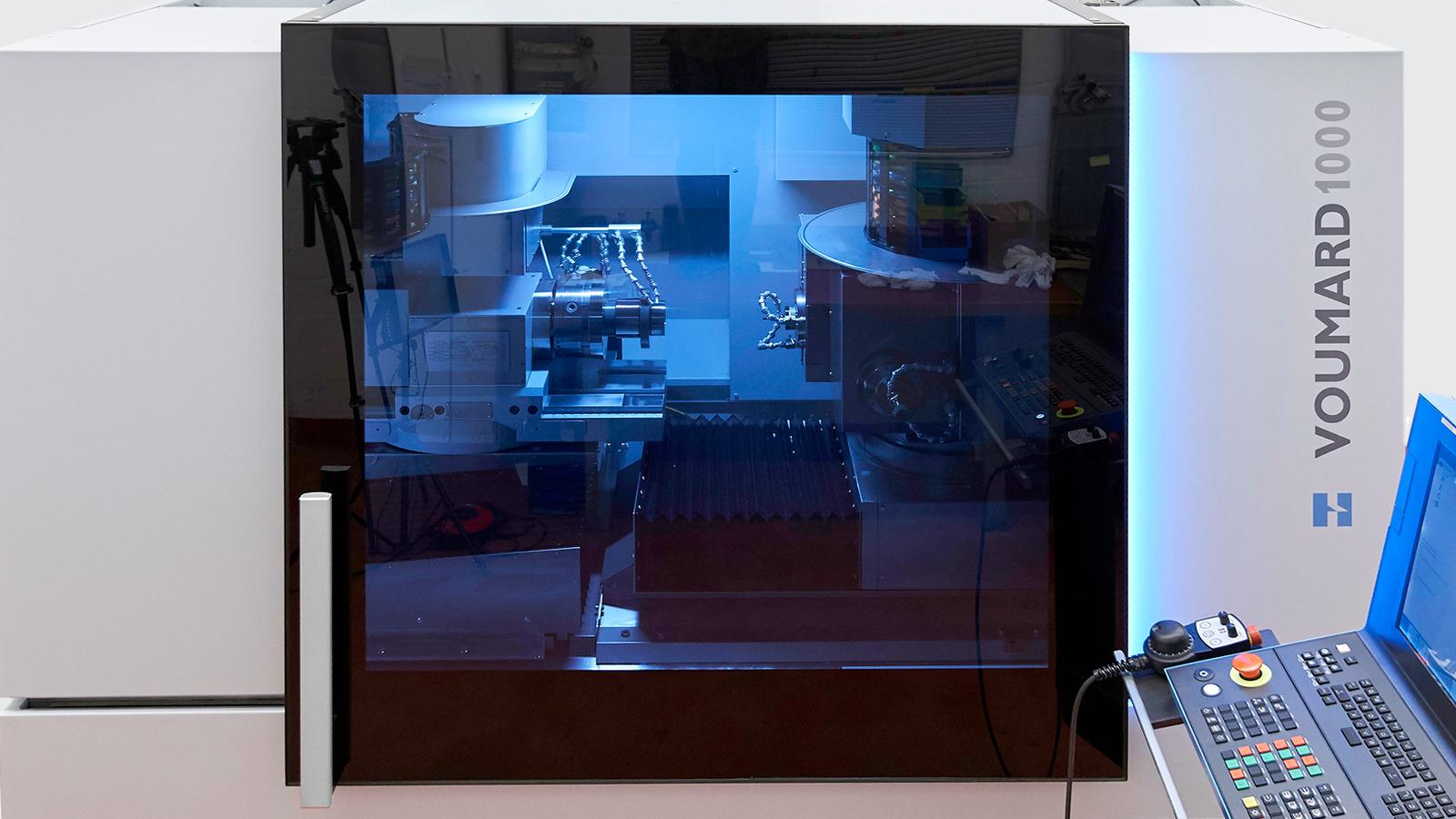

Machine safety windows in comparison

Excellent protection with

equally low weight

SICURTEC_SHIELD consists of a multi-layer polycarbonate-acrylic-glass composite and offers maximum protection for a wide range of special applications.

When looking for an absolute all-round safety glass, there is no way around SICURTEC_SHIELD. It is particularly suitable for plant housings and machine housings, security vehicles as well as construction, agricultural and forestry machines. Even when subjected to extreme violence, it convinces with its enormously high resistance. Furthermore, it offers a weight advantage of 50% compared to the glass equivalent. Thanks to its high scratch resistance, it guarantees a clear view and a long service life, even under the toughest conditions. Due to the innovative no-spall design, spalling in the event of a potential impact is a thing of the past.

Our product is tested, certified and has a lot more advantages to offer

- Particular resistant, even when subjected to extreme violence

- 50% weight advantage over glass equivalent

- High scratch resistance

- Very good transparency

- No spalling in the event of an impact

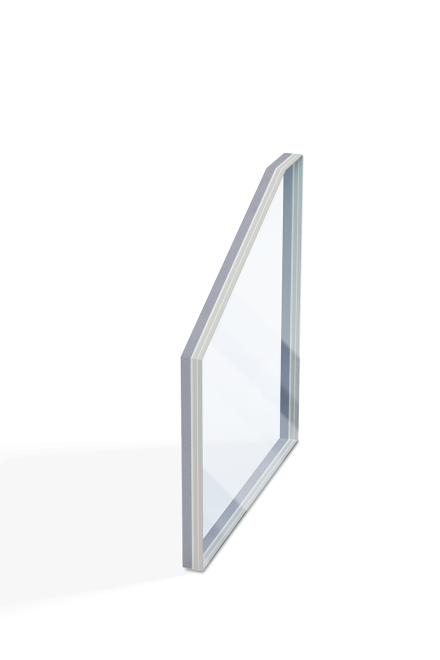

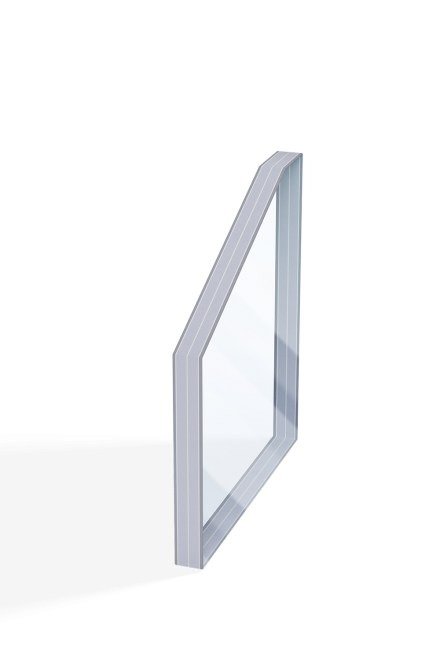

Frame systems for perfect sealing of the machine safety window

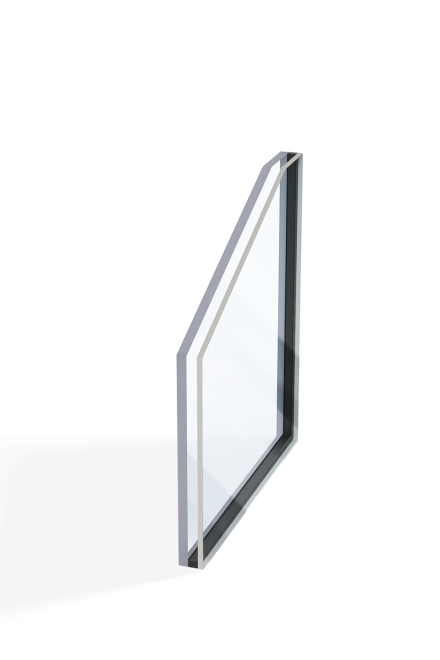

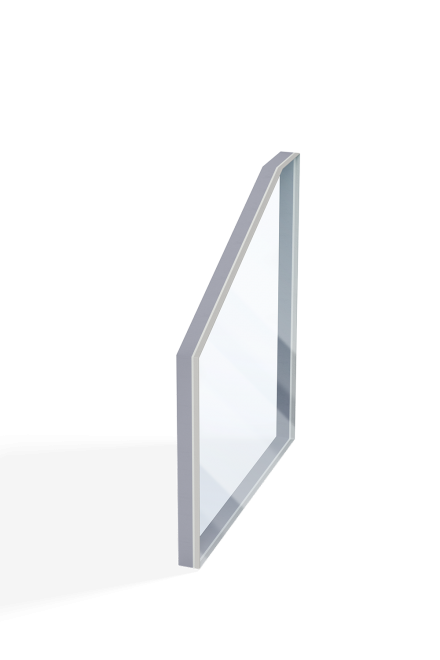

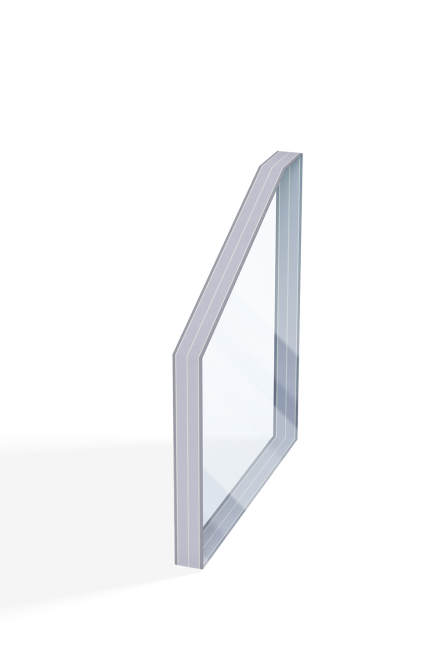

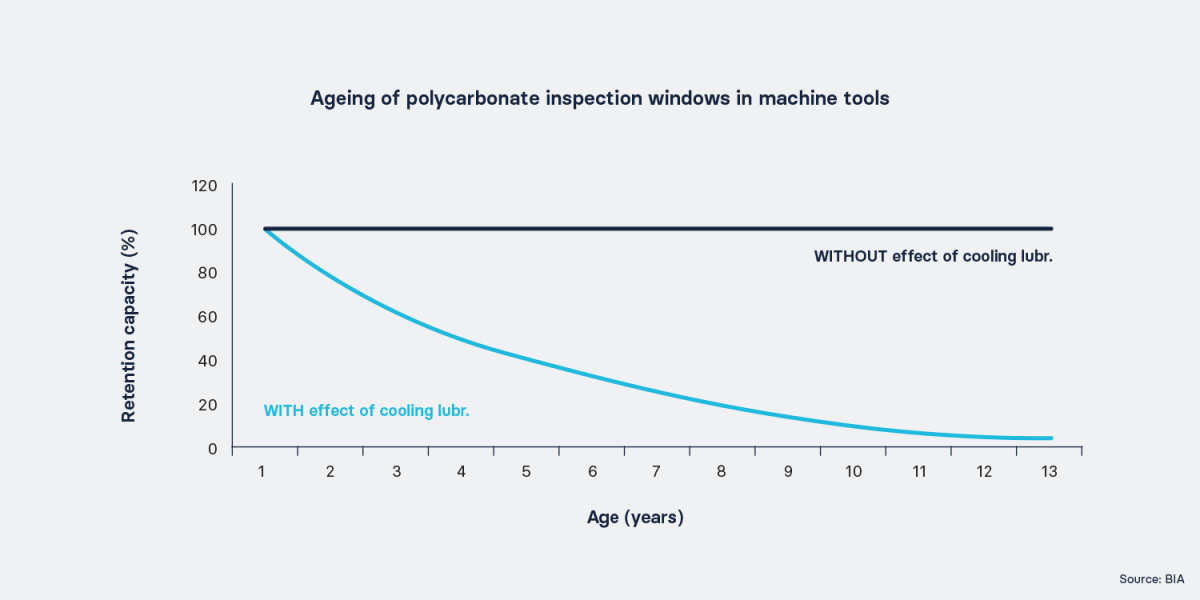

Chemical influences, such as contact with cooling lubricants, can cause considerable damage to machine safety windows. Unless, for example, the window with glass is glued into a stainless steel frame. As a all-round provider, we provide you with three standard frame profiles with L, Z and S profiles. Due to the product flexibility, all three profile types can be adapted to any pane thickness according to the desired retention effect. Same applies to frames, which are developed by us especially to customer requirements and which are produced as already glued and finished elements.

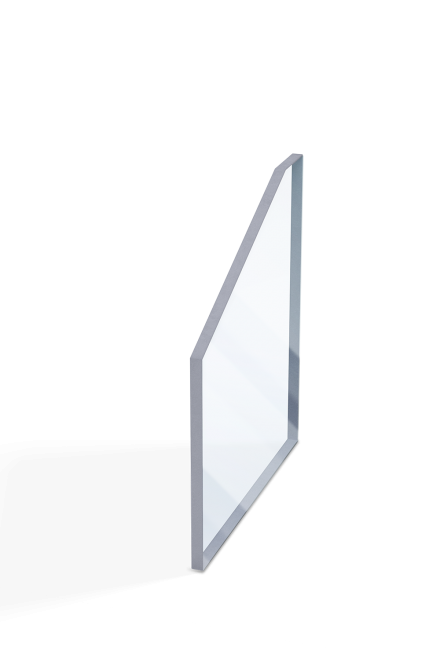

Further edge protection

Are you using an existing frame profile? No problem. The options NBR and ALU are compatible with every frame profile.